Silent Sewage Pipes

$0.00Introduction

Silent Sewage Pipes

$0.00Introduction

Silent Sewage Pipes

$0.00Introduction

Structural Lightweight Concrete (NSLC-1230)

$0.00Introduction

Structural lightweight concrete has an in-place density on the order of 1400 to 1900 kg/m3 compared to normal-weight concrete with a density in the in the range of 2000 to 2400 kg/m3. For structural applications, the concrete strength should be greater than 17 MPa. The concrete mixture is made with lightweight coarse aggregate. In some cases, a portion or the entire fine aggregate may be a lightweight product. Lightweight aggregates used in structural lightweight concrete are typically expanded shale, clay or slate materials that have been fired in a rotary kiln to develop a porous structure.

Structural Lightweight Concrete (NSLC-1230)

$0.00Introduction

Structural lightweight concrete has an in-place density on the order of 1400 to 1900 kg/m3 compared to normal-weight concrete with a density in the in the range of 2000 to 2400 kg/m3. For structural applications, the concrete strength should be greater than 17 MPa. The concrete mixture is made with lightweight coarse aggregate. In some cases, a portion or the entire fine aggregate may be a lightweight product. Lightweight aggregates used in structural lightweight concrete are typically expanded shale, clay or slate materials that have been fired in a rotary kiln to develop a porous structure.

Structural Lightweight Concrete (NSLC-1230)

$0.00Introduction

Structural lightweight concrete has an in-place density on the order of 1400 to 1900 kg/m3 compared to normal-weight concrete with a density in the in the range of 2000 to 2400 kg/m3. For structural applications, the concrete strength should be greater than 17 MPa. The concrete mixture is made with lightweight coarse aggregate. In some cases, a portion or the entire fine aggregate may be a lightweight product. Lightweight aggregates used in structural lightweight concrete are typically expanded shale, clay or slate materials that have been fired in a rotary kiln to develop a porous structure.

UPVC Door and Window Profiles containing Nanoparticles

$0.00Introduction

UPVC Door and Window Profiles containing Nanoparticles

$0.00Introduction

UPVC Door and Window Profiles containing Nanoparticles

$0.00Introduction

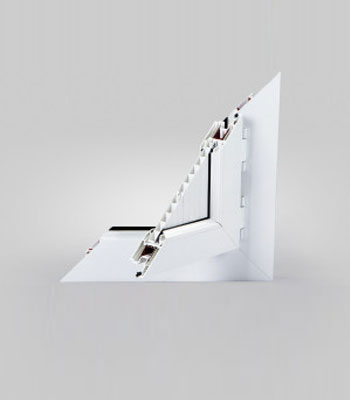

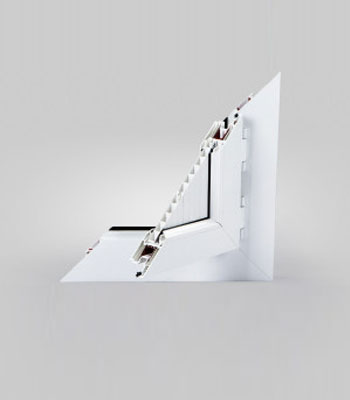

UPVC Nanocomposite Profiles

$0.00Introduction

This product is unplasticized polyvinyl chloride (UPVC) nanocomposite profile containing nanoparticles. UPVC is among the widely used polymers in building construction which is the more suitable option compared to metal and wooden profiles due to features such as high durability and performance, easy formability, low thermal expansion, prevention of the energy loss and non-flammability. However, the brittleness and loss of color during exposure to UV radiation are some disadvantages of these profiles. as a solution, nanomaterials are added to the UPVC which improve the impact strength of the product.

UPVC Nanocomposite Profiles

$0.00Introduction

This product is unplasticized polyvinyl chloride (UPVC) nanocomposite profile containing nanoparticles. UPVC is among the widely used polymers in building construction which is the more suitable option compared to metal and wooden profiles due to features such as high durability and performance, easy formability, low thermal expansion, prevention of the energy loss and non-flammability. However, the brittleness and loss of color during exposure to UV radiation are some disadvantages of these profiles. as a solution, nanomaterials are added to the UPVC which improve the impact strength of the product.

UPVC Nanocomposite Profiles

$0.00Introduction

This product is unplasticized polyvinyl chloride (UPVC) nanocomposite profile containing nanoparticles. UPVC is among the widely used polymers in building construction which is the more suitable option compared to metal and wooden profiles due to features such as high durability and performance, easy formability, low thermal expansion, prevention of the energy loss and non-flammability. However, the brittleness and loss of color during exposure to UV radiation are some disadvantages of these profiles. as a solution, nanomaterials are added to the UPVC which improve the impact strength of the product.