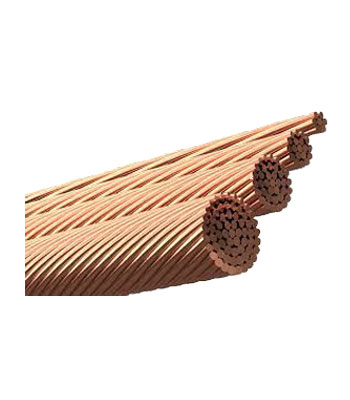

Hard Drawn Stranded Copper Conductors

$0.00Standard

- BS 7884 Edition 1997

- According to Copper Type ETP (UNS Number C11040)

Packing

- On Wooden or Metal Reels With Plastic cover

- Weight : 650 Kg/Reel

- Other weight upon request

- Without Joints

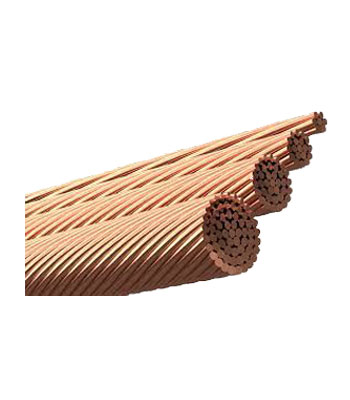

Hard Drawn Stranded Copper Conductors

$0.00Standard

- BS 7884 Edition 1997

- According to Copper Type ETP (UNS Number C11040)

Packing

- On Wooden or Metal Reels With Plastic cover

- Weight : 650 Kg/Reel

- Other weight upon request

- Without Joints

Hard Drawn Stranded Copper Conductors

$0.00Standard

- BS 7884 Edition 1997

- According to Copper Type ETP (UNS Number C11040)

Packing

- On Wooden or Metal Reels With Plastic cover

- Weight : 650 Kg/Reel

- Other weight upon request

- Without Joints

Level Wound Coil LWC Steel & Products

$0.00Using cast and draw technology are a one of the newest and advanced technology in the world. Copper tube plant has put into from 2014.

Level Wound Coil LWC Steel & Products

$0.00Using cast and draw technology are a one of the newest and advanced technology in the world. Copper tube plant has put into from 2014.

Level Wound Coil LWC Steel & Products

$0.00Using cast and draw technology are a one of the newest and advanced technology in the world. Copper tube plant has put into from 2014.

Mono-Annealed or Hard Drawn Copper Wire

$0.00Diameter

- 1.36mm – 3.599mm ± 0.1

Physical Characteristics

- Single Wire

- Annealed or Hard Drawn

- For Annealed Copper Elongation (A250) Table 1 on ASTM B3 Standard

- For Annealed Copper Resistivity (20ºC) >0.15328 Ωg/m2

- For Hard Copper Resistivity (20ºC) >0.15940 Ωg/m2

- For Hard Copper Tensile Strength Table 1 on ASTM B1 Standard

Mono-Annealed or Hard Drawn Copper Wire

$0.00Diameter

- 1.36mm – 3.599mm ± 0.1

Physical Characteristics

- Single Wire

- Annealed or Hard Drawn

- For Annealed Copper Elongation (A250) Table 1 on ASTM B3 Standard

- For Annealed Copper Resistivity (20ºC) >0.15328 Ωg/m2

- For Hard Copper Resistivity (20ºC) >0.15940 Ωg/m2

- For Hard Copper Tensile Strength Table 1 on ASTM B1 Standard

Mono-Annealed or Hard Drawn Copper Wire

$0.00Diameter

- 1.36mm – 3.599mm ± 0.1

Physical Characteristics

- Single Wire

- Annealed or Hard Drawn

- For Annealed Copper Elongation (A250) Table 1 on ASTM B3 Standard

- For Annealed Copper Resistivity (20ºC) >0.15328 Ωg/m2

- For Hard Copper Resistivity (20ºC) >0.15940 Ωg/m2

- For Hard Copper Tensile Strength Table 1 on ASTM B1 Standard

Multi Copper Wire

$0.00Diameter

- 0.155mm – 0.40mm

Physical Characteristics

- Multi Strand Min.2 Strand Max. 16 Strand

- Annealed

- Elongation (A250) Table 1 on ASTM B3 Standard

Multi Copper Wire

$0.00Diameter

- 0.155mm – 0.40mm

Physical Characteristics

- Multi Strand Min.2 Strand Max. 16 Strand

- Annealed

- Elongation (A250) Table 1 on ASTM B3 Standard

Multi Copper Wire

$0.00Diameter

- 0.155mm – 0.40mm

Physical Characteristics

- Multi Strand Min.2 Strand Max. 16 Strand

- Annealed

- Elongation (A250) Table 1 on ASTM B3 Standard

Oxygen Free Copper Rod

$0.00Technical Specification

- Electrical Conductivity ≥% 101 %IACS

- Oxide Film Thickness ≤ 15-50 Å

- Tensile Strength 175 N/mm²

- Elongation (A250) 38%

- Hydrogen Embrittlement ≥10bends

- 10/10 Twist No defect such as Checks , Flakes , Seams or Overfills

- Drawability 0.05 mm

Oxygen Free Copper Rod

$0.00Technical Specification

- Electrical Conductivity ≥% 101 %IACS

- Oxide Film Thickness ≤ 15-50 Å

- Tensile Strength 175 N/mm²

- Elongation (A250) 38%

- Hydrogen Embrittlement ≥10bends

- 10/10 Twist No defect such as Checks , Flakes , Seams or Overfills

- Drawability 0.05 mm

Oxygen Free Copper Rod

$0.00Technical Specification

- Electrical Conductivity ≥% 101 %IACS

- Oxide Film Thickness ≤ 15-50 Å

- Tensile Strength 175 N/mm²

- Elongation (A250) 38%

- Hydrogen Embrittlement ≥10bends

- 10/10 Twist No defect such as Checks , Flakes , Seams or Overfills

- Drawability 0.05 mm

Oxygen Free Silver Bearing Copper Rod

$0.00Diameter

- 8 mm

- 12.5 mm

- 20 mm

- 23 mm

Technical Specification

- Copper include silver Ag : 0.04% , 0.07% , 0.1% O:0 – 5 ppm Cu : Rem

- Electrical Conductivity ≥% 100 % IACS

- Tensile Strength 175 N/mm²

- Elongation (A200) ≥ 38%

- Hydrogen Embrittlement without breaking

- Tensile Strength

Standard

- EN1977(March 1998)

Oxygen Free Silver Bearing Copper Rod

$0.00Diameter

- 8 mm

- 12.5 mm

- 20 mm

- 23 mm

Technical Specification

- Copper include silver Ag : 0.04% , 0.07% , 0.1% O:0 – 5 ppm Cu : Rem

- Electrical Conductivity ≥% 100 % IACS

- Tensile Strength 175 N/mm²

- Elongation (A200) ≥ 38%

- Hydrogen Embrittlement without breaking

- Tensile Strength

Standard

- EN1977(March 1998)

Oxygen Free Silver Bearing Copper Rod

$0.00Diameter

- 8 mm

- 12.5 mm

- 20 mm

- 23 mm

Technical Specification

- Copper include silver Ag : 0.04% , 0.07% , 0.1% O:0 – 5 ppm Cu : Rem

- Electrical Conductivity ≥% 100 % IACS

- Tensile Strength 175 N/mm²

- Elongation (A200) ≥ 38%

- Hydrogen Embrittlement without breaking

- Tensile Strength

Standard

- EN1977(March 1998)

Pancake Steel & Products

$0.00Using cast and draw technology are a one of the newest and advanced technology in the world. Copper tube plant has put into from 2014.

Pancake Steel & Products

$0.00Using cast and draw technology are a one of the newest and advanced technology in the world. Copper tube plant has put into from 2014.

Pancake Steel & Products

$0.00Using cast and draw technology are a one of the newest and advanced technology in the world. Copper tube plant has put into from 2014.